1.2 Layout and Scale of Three Gorges Project

The Three Gorges Dam is a conventional concrete gravity dam that comprises three sections: one retaining dam, the intake dam, and the non-overflow dam (CTGPC, 2002). It is 181 meters high and 2309 meters long (ibid). Normal pool level is 175 meters, with the crest elevation at 185 meters, and 198 meters thick at the bottom, and 15 meters at the crest. The dam is designed to withstand an earthquake intensitie of up to magnitude 7 on the Richter scale (ibid).

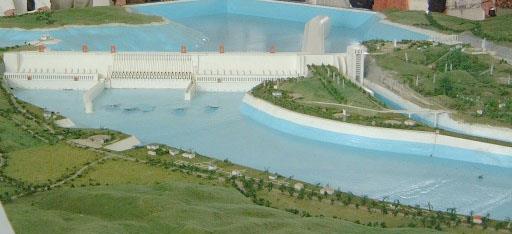

Figures 1- 5 & 1- 6 below are taken from the perspective facing upstream of the river. 22 gated spillways located in the middle of the river course (shown in Figure 1-5). 2 powerhouses were constructed underground on both side of the dam body. The five-step ship lift is located on the right of the dam body. The ship locks (figure 1-6) are to the right of the ship lift (ibid).

Figure 1-5: Model of layout of Three Gorges Project (source: CRWC, 2010)

Figure 1-6: Model of layout of Three Gorges Project ship lock (source: CRWC, 2010)

The magnitude of the main construction facets of the Three Gorges Dam has been enormously intrusive of the earth. The project involved:

1) Employed approximately 250,000 workers to complete in the construction of the Dam (U.S. Embassy (Beijing) online).

2) Excavated 102.83 million cubic meters of stone and earth (Power-technology.com).

3) Refilled 31.98 million cubic meters of stone and soil (Power-technology.com).

4) Mixed and poured 27.94 million cubic meters of cement (Power-technology.com).

5) Erected 281,000 tons of metal structures and 56 million cubic feet of timber (Chetham, 2002; Liang, 2010).

6) Made and erected 354,000 tons of reinforcing bars (Liang, 2010).

7) Built 231,000 square meters of leak-proof concrete walls (Liang, 2010).

8) Installed 256,500 tons of steel and 26 electricity-producing turbine-generators units (not including six 700 million watts units in the Right Bank Underground Powerhouse) (U.S. Embassy (Beijing) online; Power-technology.com).

As observed earlier, the reservoir created by the dam extends about 662 kilometers in length and has an average width of 1.12 kilometers when the water level up to its maximum at 175 meters. The total surface area of the reservoir is therefore 1,045 square kilometers, having a total storage capacity of 39.3 billion cubic meters (CTGPC, 2002; U.S. Embassy (Beijing) online). The Three Gorges Dam is specifically the world’s largest dam in two facets: it is the largest water conservation project on the globe and the largest hydropower plant ever created (U.S. Embassy (Beijing) online; Allin, 2004; Gleick, 2008)

To provide some sense of comparison of volume capacity, below is the respective ranking list for the top 10 of the largest dam structures in the world.

Table 1-1: Top ten list of the largest dam in the world (Source: Department of the Interior, Bureau of Reclamation and International Water Power and Dam Construction)

| Dam | Location | Volume (cubic meters) | Year completed | |

| 1 | Three Gorges | China | 39,300,000 | 2009 |

| 2 | Syncrude Tailings | Canada | 540,000 | Under Construction |

| 3 | Chapetón | Argentina | 296,200 | Under Construction |

| 4 | Pati | Argentina | 238,180 | Under Construction |

| 5 | New Cornelia Tailings | United States | 209,500 | 1973 |

| 6 | Tarbela | Pakistan | 121,720 | 1976 |

| 7 | Kambaratinsk | Kyrgyzstan | 112,200 | Under Construction |

| 8 | Fort Peck | Montana | 96,049 | 1940 |

| 9 | Lower Usuma | Nigeria | 93,000 | 1990 |

| 10 | Cipasang | Indonesia | 90,000 | Under Construction |

Figure 1-7: Comparison of satellite images: before and after the construction of the Three Gorges Dam (Source: Science 20.com. Credit: NASA/USGS)

Dam Specifics

To summarize: the Three Gorges Dam is a concrete gravity structure, made of 14.86 million cubic meters concrete. The central axis length of the dam is 2309.47 meters, and the elevation of the dam is 185 meters (CTGPC, 2002).

The spillway dam is located in the middle of the river course (ibid). The length of its front section is 483 meters, with 23 flood discharge holes and 22 surface sluice gates (ibid). The surface sluice gates are 8 meters wide each, with an elevation at 158 meters (ibid). The dimensions of the flood discharge holes are 7 meters wide and 9 meters high, with the elevation of the inlets at 90 meters (ibid). On both sides of the spillway dam there exist an intake dam and non-overflow dam (ibid). The maximum discharge capacity of the dam is 102,500 cubic meters per second at the maximum pool level of 180 meters, the biggest pool level in the world (ibid).

Figure 1-8: The technical design of the Three-Gorges-Dam (Source: Bogena, 2004)

Figure 1-9: The Three-Gorges-Dam (Source: Asian Infrastructure).

Power Plant

There are actually two powerhouses: one is located on the left bank with 14 sets of power generators, and the other is located on the right with 12 sets of power generators, thus producing a total capacity of 18.2 million kilowatts, also the largest production output of any dam in the world (CTGPC, 2006). The Three Gorges Dam is capable of generating 84.7 billion kilowatts per hour annually, making it the single largest power plant in the world (ibid). It surpasses the Itapúa Dam built jointly by Brazil and Paraguay, by being approximately 1.44 times bigger (Hull, 2009). The transmission lines of two ±500 kilovolt DC transmission lines to East China, and eleven 500 kilovolt AC lines to central China, are also the biggest scale for transmission lines in the world (CTGPC, 2006). The space and intake excavations undertaken in the construction of the underground powerhouse on the right bank, served ultimately to house six more units, each of which has a capacity of 770 million watts (ibid).

Figure 1-10: A hydroelectric generator at the Three Gorges Power Plant (Source: China.org.cn)

Three Gorges Ship Lock

There exists a two lane five-step inland river ship lock on the left bank to lift or lower commercial and passenger vessels weighing up to 10,000 tons, thus allowing passage through the dam site from 50 meters downstream to 170 meters upstream (CTGPC, 2002). The operating water head is 49.5m for a gate, which also exceeds the world record (ibid). Each head has a lock chamber of 280 meters in length and 34 meters in width, with a minimum water depth of 5 meters, producing a maximum water discharge amount of 26,000 cubic meters (ibid). It takes about 3 hours to pass through the locks (ibid). The volume of trade passing through the locks is expected to increase from 10 to 50 million tons per year and consequently reduce a cost of about 35 percent (ibid). Because the huge dam and the capacious lake are juxtaposed, it is possible to maintain two-way navigation in the previously dangerous gorges reach between Yichang and Chongqing (CTGPC, 2006).

Figure 1-11: Profile of the double-way and five-step ship lock (source: CRWC)

Figure 1-12: The Three Gorges Dam Shiplocks (source: CTGPC)

Ship Lift Type

Single-way and one-step vertical ship lift facilities, with counterbalanced ship containers are employed by the Three Gorges Dam complex to allow smaller vessels to pass through the dam quickly. It has a total length of about 6000 meters and consists of two-way approach channels, lock heads and ship chamber section (CTGPC, 2002). The ship lock is capable of lifting a maximum 3000 tons vessel in a 113 meters stage (ibid). The ship chamber has outline dimensions of 132 meters long, 23.4 meters wide and 10 meters high, and the effective water area contained in it is 120 meters in length, 18 meters in width , and 3.5 meters in depth, making it the largest in the world in terms of the main technical parameters (ibid). Due to the enormous dimensions of the Dam, its complex engineering solutions, complicated operating conditions, and fastidiously demanding requirements to ensure its safety and reliability, the TGD’s ship lift is the most complicated structure among any of the existing dams in the world, in terms of design, manufacture and technical difficulties in construction (ibid).

Table 1-2: Three Gorges Dam Physical Summary (source: www.irn.org, 2004)

| Location Dam Site Sandouping, Hubei Province, China Dam Crest 185 meters Dam Length 2,000 meters |

| Reservoir Specifications Normal Pool Level 175 meters Flood Control Level 145 meters Total Storage Capacity 39.3 billion cubic meters Flood Control Storage 22.1 billion cubic meters Navigation Reservoir level raised by 10-100m to allow 10,000 ton ships to Chongqing |

| Power Generation Installed Capacity 17,680 million watts Unit Capacity 26 units, 680 million watts per unit |

| Inundation Land 632 kilometers-long, 19 cities, 326 towns Arable Land 30,000 hectares Population 1,130,000 people |

Figure 1-13: Profile of the vertical ship lift (source: CRWC)

Appendix Construction

Additional infrastructure, such as the relatively new major highway road that follows the Yangtze River, or the TGP Expressway, as it is called, was built to connect metropolis Chongqing to the dam site in order to transport the tons of construction materials to the otherwise inaccessible mountainous areas in which the construction site is located. In addition, there are 34 bridges and 5 double-lane tunnels, including a 3,610-meter long single-lane tunnel has been built along with the highway road and is the longest of its kind in China (Bogena et al., 2004). An airport and a major suspension bridge, the Xiling Yangtze Bridge, were also built to improve the overall transportation condition in this region (ibid).

Construction Periods

To make comprehensible, the temporal chronology of the Dam’s construction has been divided into three stages:

1993 to 1997 was the first-phase of the Project, involving the preparatory and planning of the construction of the dam. Completion of this stage was signaled by the damming of the Yangtze River on November 8, 1997 (CTGPC, 2002; Bogena et al., 2004).

The second phase ran from 1998 to 2003. This phase was completed when the first generator unit in the left-bank power plant was connected to the main power grid and the permanent ship lock began operation (ibid).

The third phase was completed in 2004-2009. This final phase includes the installation and initiation of power of all 26 turbo generators (ibid).